Fully automated grinding and polishing with CNC-controlled processing machines for industrial parts in large series made of aluminum, brass, copper, bronze, stainless steel, steel or titanium.

Consistently high precision – even in series

To meet the highest demands on quality and reproducibility, we use automated CNC-controlled processing machines for series production.

Your benefits at a glance:

Automated polishing at the highest level

Very smooth or high gloss surfaces require a lot of time and experience in the processing. The combination of years of experience in manual polishing and precise CNC robot arm programming are the prerequisite for continuously high quality in series.

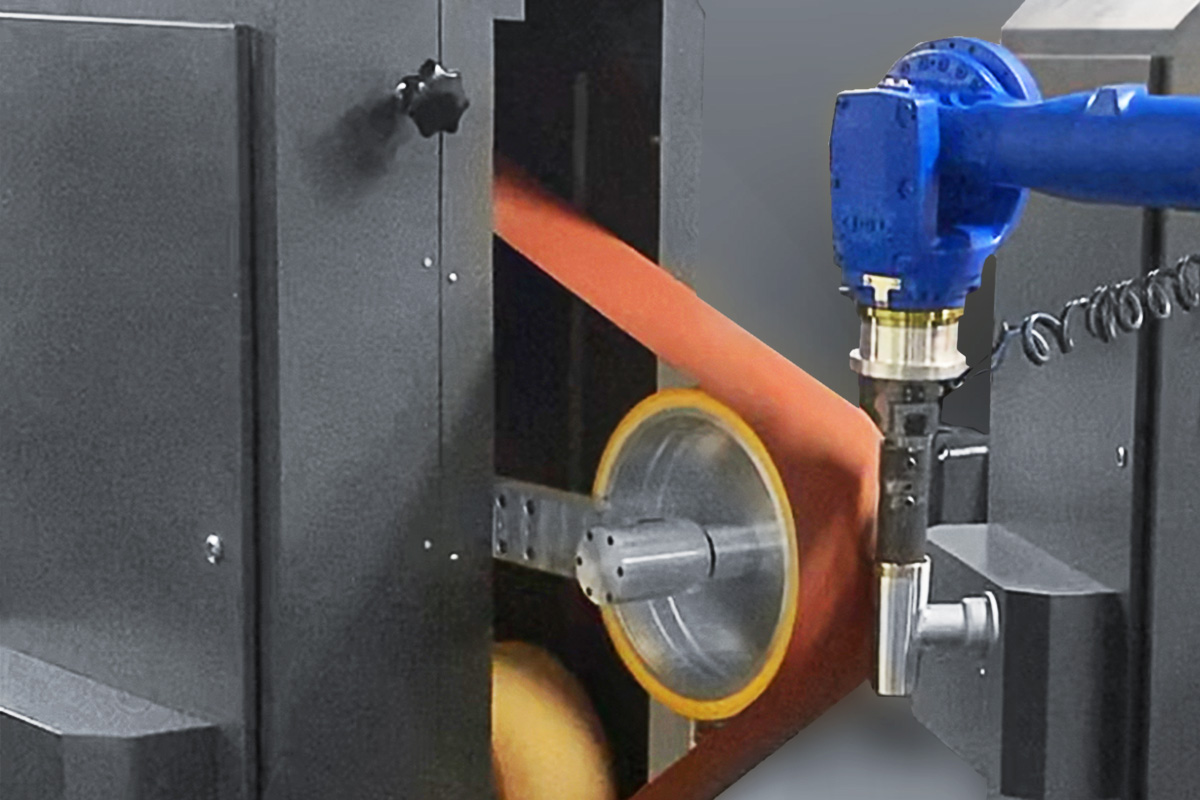

The perfect cut through the use of robotics

For permanent high quality, we rely on the latest robot technology for handling the workpieces. An optimized workflow and state-of-the-art grinding processes ensure outstanding results. To ensure that every workpiece can be processed optimally, we develop our own robot grippers and use individual parts magazines in production to provide the workpieces.